ISO 14998 V0 C-FLEX Multi Stage Cementing

The Cflex® cementing system improved annular seal integrity and overcomes the shortcomings of previous stage cementing technology.

The Cflex® cementing system improved annular seal integrity and overcomes the shortcomings of previous stage cementing technology.

Egina, Akpo

Delivered 2 CFLEX

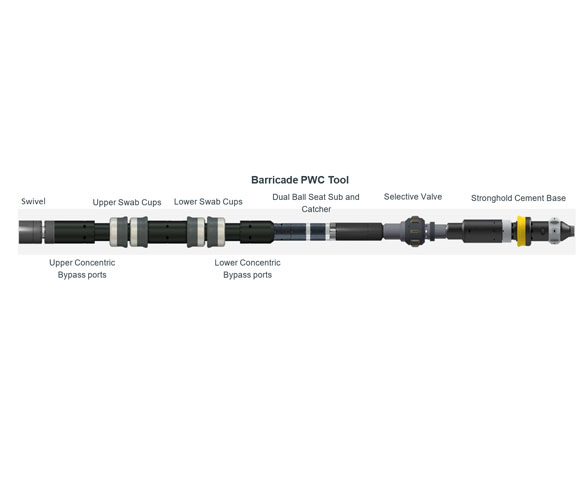

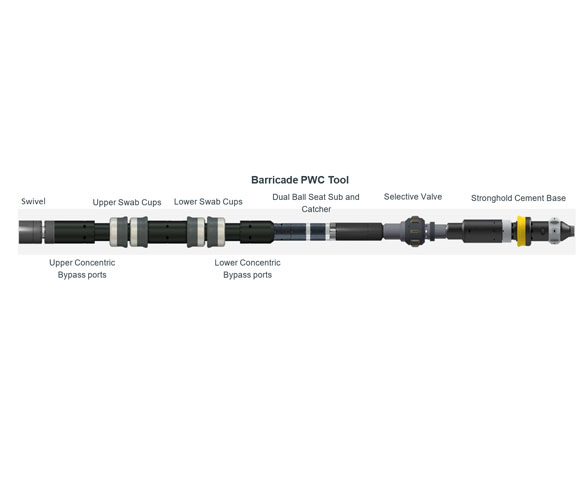

System Overview - The Stronghold® Barricade® System is a perforate, wash and cement placement system that reduces plug and abandonment (P&A) costs by creating a rock-to-rock barrier in one trip

With the addition of the one-trip Tubing Conveyed Perforation (TCP) module, the Barricade® System is designed to wash and clean the annulus of a perforated casing or liner in a selected formation zone or between casings, then accurately place a permanent barrier

After the annular cleaning phase, high circulation rates and pipe rotation enhance debris removal from the washed annulus and out of the well

A one-trip operation with the Barricade® System consists of:

BONGA FIELD

4 runs